Strietman CT2 review

by Simone Forgia, Claudio Santoro

In today's consumer society, there are many products created by multinationals with hundreds if not thousands of employees, aimed at mass production and with little regard for construction quality. Although many experts with the most disparate specializations for every aspect might work on them, then we arrive at a product to which so many people have contributed that no longer has any kind of identity. It is therefore difficult to still find a product designed, developed, manufactured and assembled by the same person; this however, is precisely the case of the Strietman and in particular of the CT2 model that we are going to review today.

The CT2 represents the third model aimed at the espresso enthusiast market handcrafted by Wouter Strietman in Eindhoven, The Netherlands. Its design is Nordic: elegant, slender and partly minimalist; while the materials range from stainless steel to brass, copper and wood for the handles. Included are a lid to be placed over the grouphead / boiler to retain heat and prevent dust from entering, a massive bottomless portafilter in polished brass, a tamper with a slightly convex base and a small funnel to facilitate the introduction of ground coffee in 4 filters specially made by IMS; two 15 grams and two 18 grams.

On first impact, the feeling it gives us is certainly that of a quality product. The alternation of the three colours of steel, brass and copper in addition to the contrast of the mirror polish with the brushed parts give it a great stage presence while the walnut wood on the contact parts makes it more pleasant to use. The mighty front base is completely devoid of electronics, thus reducing the possibility of it coming into contact with splashes of water and at the same time ensuring great stability to the machine, preventing it from tilting or moving when in operation. The switch is very solid and has two lights, one white which indicates the operation of the unit and a red one relating to the switching on or off of the resistance. The first in our case flashed slightly in contrast to the second which did not present this small annoyance. While in regard to the drip tray plate we would have preferred if it had been finished on both sides, so that it could also be used on the opposite side.

Being a machine with an open boiler, it does not go under pressure and therefore it is not able to generate steam for those wishing to froth milk but to the detriment of this it presents several really interesting technical solutions. The boiler and the grouphead have in fact been united and made to become one; in this way you can directly adjust the desired temperature through a thermostat and you do not have to worry that the water cools or overheats when passing through the two bodies. The capacity is limited to 3 decilitres but can become unlimited if you consider that at any time you can top up with additional water (cold or already hot) without having to turn everything off. The heating element is placed inside the grouphead itself and is not in contact with the water, in this way it is protected from limescale and if you forget to fill the boiler with water before turning it on, there is no danger that it might burn. The good thermal conduction over the entire surface is guaranteed by the brass and copper which, however, to avoid direct contact with water and the premature oxidation of the materials, were pressed together with a very thin layer of stainless steel of only 200 microns creating an intercrystalline structure.

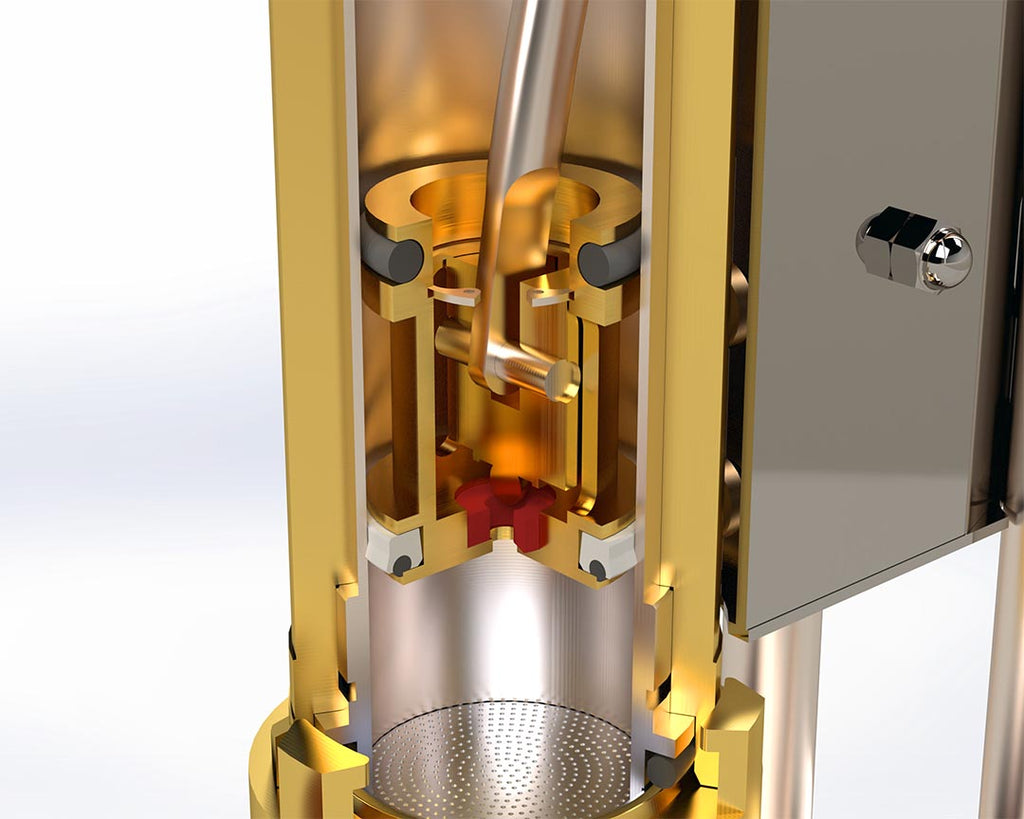

Another point that deserves special attention is the piston; far more complex than those found on almost all other machines but which allows water to pass through it as soon as the lever is raised by a few millimetres and to stop this action as soon as it is released, in any position, closing the hole at the centre of the lower part again. This system, illustrated in the image below, ensures that there is not the classic sucking effect that disturbs the coffee puck and the portafilter, which can be attached both from the right and left side, can already be fixed from the moment the lever is in the resting position. Furthermore, the lever will never be "spongy" due to the fact that as soon as it is lifted, the air escapes from under the piston and is vented upwards.

Illustration of the piston mechanism

Once switched on, the Strietman CT2 is extremely quiet and if it weren't for the little white light it would even be difficult to distinguish when it is running from when it is not. It only takes a few minutes to reach temperature, after which, thanks to the system described above, it is immediately usable and there is no need to purge the false pressure, perform false pumping or other similar manoeuvres that instead are necessary on other competitor models that function in a different way. Its height and high stroke of the lever, means that when completely raised it ends up quite high and here is where its particular curvature comes to our aid. Despite this, it can still be a little uncomfortable to use if you are not very tall and we generally find it easier to place it on a surface of about 10 cm. lower than usual. The optimal posture to assume is also a bit different from the other competitor models: further away, central and if you want you can also use both arms without worrying that everything will tip forward as even under stress it shows no weaknesses. A negative point goes to the space between the filter holder and the drip tray, which is very short and therefore allows you to use only medium-low or low cups and the use of a scale is made impossible in many cases. This aspect also makes it difficult for those interested to observe the extraction through a mirror. In spite of this, the volume of our espresso, benefits from these characteristics allowing us to exceed 40 grams without problems.

Adjusting the water temperature is theoretically very simple as there is a special knob with a scale from 80°C to 96°C that acts directly on the thermostat adjustment; however, on the unit we used for the test, this knob went well below the minimum indicated and at its maximum reached 95°C, thus missing the last step. Furthermore, the red light simply indicates whether the resistance is on or off but we do not know if the temperature is actually the correct one. So, if for example we would want to adjust the thermostat to 88°C, once it reaches that temperature the resistance switches off and if we move the setting to 92°C it will turn on again until this measurement is reached. This logic, however, does not also apply in reverse as if we had to move the knob from 88°C to 84°C, the heating element (rightly) will remain off and with it the red light will not turn off. The quickest ways to lower the temperature a few degrees until it reaches the desired value are to remove the lid and let out a little steam, add a small amount of cold water or wait 1-2 minutes.

The website indicates that the temperature of the grouphead, when filled to its maximum capacity and with the lid on, fluctuates with a differential of 3°C and that therefore the real water temperature will never be more or less than 1.5°C than indicated. However, as can be seen from the graph below that we made by placing a k-type probe directly in the water near the piston, the degree of fluctuation is a little larger than described.

Temperature graph with the machine set to 92°C

In particular, it can be observed how the desired temperature is approached only after the resistance switches off for the second time and considering only the values after 8 minutes from switch on over the period of one hour, the temperature was on average 1.77°C less than what was set with maximum and minimum peaks of + 3.4°C and -6°C. The less water you have inside the boiler, the less stable the temperature will be, furthermore, by removing the lid the measurements will be on average 2°C lower. In addition, the graph shows that in our case we obtained the most correct temperature between 15-20 minutes after switching on, while after 30 minutes it was constantly below the target. In general, however, this is not a machine designed to remain on for hours as the water slowly continues to evaporate and there is the risk that it will dry out and the seals will dry.

Therefore, although the value indicated by the knob represents only indicatively the real water temperature, this does not mean that our extractions cannot be accurate. In fact, for the most demanding, it is possible to use the CT2 in a more manual way, by inserting a probe directly into the water as we did and always have the measurements in real time. In this way you can turn on the machine and adjust the thermostat to the maximum of its scale (96°C) wait for the probe to indicate the desired temperature and as soon as that moment arrives, turn the knob downwards again until the heating element goes out. By doing so, you can extract at the desired values with absolute precision even after only 10 minutes. Finally, it must be said that even the pre-infusion pressure is fully managed by us as it is an open boiler model and therefore if we do not apply force on the lever it will be very delicate and without any type of pressure. This feature also allows to make cold extractions.

Extraction with the 18 grams basket

Staying on the subject of extractions, in the first tests we experienced a “donut effect” observing the flow from the bottomless portafilter. In other words, during the preinfusion phase we saw the first drops of coffee appear on the entire circumference of the filter and only later also in the centre. This indicated that the water passed more easily along the edges of the filter and we attributed this problem to the funnel supplied which, instead of resting on the lip of the filters, enters inside and when it is removed it leaves an empty space. In subsequent extractions, however, we solved this problem with a better distribution technique using the WDT (Weiss Distribution Technique).

Coffee pucks after extraction

As illustrated by the picture above, however, in some cases we encountered the opposite problem, i.e., a slow flow along the circumference and consequently the coffee solids dissolved in the water did not end up in our espresso but were trapped on the bottom of the coffee puck. Although we could not ascertain this phenomenon, in our view it was due to the slightly convex tamper and therefore the parts of ground along the edges were pressed more against them and consequently slowing the flow. In any case, in general, the results obtained were good and the expressos well balanced.

Finally, as far as maintenance is concerned, there are only a few seals, the piston for example can be easily removed without the aid of any tools and there are clear instructions for each step on the manufacturer's website. However, it is a machine to be treated with care, not to be abused and if you want to avoid a patina due to oxidation on copper and brass, a little maintenance should be done once every two months with special products as they are only polished and protected with a very thin layer of grease and not plated or treated in any other way. Further care must be taken with the drip tray, which if not cleaned and dried regularly can easily be stained by coffee residues.

The Strietman CT2 is therefore a machine for true espresso purists, those who want full control of the extraction and are not interested in making cappuccinos or who already have an alternative for that. It is a machine to be admired for the audacity of the design, the build quality, its engineering solutions and, as the lack of a two-spout filter holder confirms, it is not designed for large volumes although it does not suffer from overheating. Even though it may appear very simple in appearance, its sleek and elegant lines actually contain a lot of technology. It is a machine that you have to take care of but at the same time when you use it, it makes you slow down, enjoy the moment and take care of yourself.

Strietman CT2 with tamper, funnel and filter supplied

Simone, editor of The Lever, embarked on a new journey starting from July 2025.

He is volunteering in Nicaragua to learn about coffee farming and is documenting his journey through physical letters sent directly to your doorstep.

Curious to hear his experiences?